~ Reactor manufacturers’ advanced pressurized water reactor farce is exposed:

By Goto Masashi, former Toshiba nuclear engineer

1. Post-Fukushima nuclear accident nuclear power plant (NPP) restarts sluggish

Today, nearly 12 years after the reactor core meltdowns at Fukushima Daiichi Nuclear Power Station (FDNPS), only ten reactors have been restarted. As a top priority, due to the need to clarify the cause of such a huge accident in a pressurized water reactor (PWR), at least four accident investigation commissions, including the National Diet of Japan Fukushima Nuclear Accident Independent Investigation Commission (NAIIC), were set up and publicized their conclusions in a short span of time. Regarding the accident’s cause, however, since access to the inside of the containment vessel is still limited, we only know about half of what happened. In particular, the seven recommendations by NAIIC* were highly significant from the viewpoint of preventing a reoccurrence of a similar accident, but along with the later change of government these have simply been ignored and not discussed in the Diet.

2. NPP aging is a scientific and engineering problem

Gradually shifting the energy policy put forward after the Fukushima nuclear accident to forego reliance on nuclear power, in the Sixth Strategic Energy Plan, approved by Cabinet decision in October 2021, a figure of 20 to 22% was indicated as the target proportion of nuclear power in the energy mix in 2030. Putting pressure on the Nuclear Regulation Agency (NRA) to encourage reactor restarts and being unscientific about 40-year reactor lifetime, the government started talking about getting the maximum possible out of aged reactors. NRA made it known that a rethink of the 40-year operating period was a political decision and nothing to do with regulation.

However, what I find worrying is how dangerous it is and how the risk of accidents is dramatically increased by simply shouting out that it is necessary to extend the operating period of aged reactors in order to run them.

I therefore believe that the notion that accidents become more likely to occur as old reactors deteriorate, and thus a predetermined operating period is imposed, at the end of which reactors should be shut down and thoroughly inspected, is a scientific and engineering decision.

3. High-temperature gas reactor – difficulties in reaching practical realization

A movement has surfaced to resuscitate the “high-temperature gas reactor” and “small modular reactor,” known as “advanced reactors” that were being researched 30 or 40 years ago. The high-temperature gas reactor uses ceramic particles sheathed in several layers as the fuel, graphite as moderator, and helium as the coolant. As the exit temperature of the hot helium gas reaches about 950°C, pipes are double-layered. The temperature of the reactor environment is about three times higher than the approximately 300°C of the PWR, making practical realization of this reactor difficult to achieve.

4. Uncompetitive Small Modular Reactors (SMRs)

When judging the pros and cons of the application of a novel technology, rather than its merits, it is necessary to assess whether a large-scale accident could occur, and whether or not there are manufacturing problems. For instance, there might be significant demerits with the modularization engineering method depending on the environment. In fact, in the large-scale modular engineering method practiced by Westinghouse, bought out by Toshiba, a number of faults resulted in serious re-engineering obstacles, causing Toshiba itself to self-destruct due to unbearable losses.

In the engineering method under which nuclear power plants are a job-shop product, the basis is the so-called “build-to-order production” where each component is produced according to the order, and is the complete opposite of the mass production technology for items such as small modular reactors. SMRs, nuclear reactors and steam generators, for example, are built as integrated units, the number of units being increased to attain the desired output. Cost reductions can be expected from mass producing identical modules in a factory, but if a fault is discovered during manufacture, it’s too late to do anything about it. To make mass production feasible, the whole process from design to manufacture must be almost 100% perfect. In the first place, small modular reactors are intended for solitary islands and remote areas, and thus demand is limited. From the viewpoint of economic performance, there is no comparison with large-scale PWRs.

5. Reactors deteriorate even during shutdown

The main issue in the discussion is whether or not the downtime period should be included in the 40-year operating period of nuclear reactors after the Fukushima nuclear accident and periods of suspension of operations due to lawsuits and other reasons.

In the first place, it is hard to distinguish between the deterioration that advances while the plant is in operation and the deterioration that occurs while it is shut down. For instance, it is thought that the fatigue failure that occurs under a corrosive environment consists of both fatigue that advances due to repeated load on a component during operation and corrosion that advances when there is no repeated load on the component. Due to various kinds of environmental conditions, it is entirely possible that deterioration will advance even when the reactor is shut down. There are no scientific or engineering grounds for excluding downtime from the operational period.

6. Are NPP construction companies seeking out an advanced PWR?

Even so, this loosening of restrictions on operating periods would still not be sufficient to secure the necessary operating NPPs up to the 2050s. What has been taken up now, with respect for the relatively long historical experience with the PWR, is an “advanced PWR” to which several improvements have been made to the reactor type and structure from the viewpoint of safety.

According to the Denki Shimbun (Electricity Newspaper) of November 10, 2022: “As the advanced PWR can make use of mature existing technology and supply chains, construction time and costs are easy to estimate.”

Explaining these features is Toshiba Energy System’s Managing Director and CNO (Chief Nuclear Power Officer) and chief nuclear power engineer, Usui Hidekazu. It was reported that Toshiba is in the process of developing an advanced PWR known as “iB1350,” Hitachi also made a similar claim. In late August, PM Kishida Fumio instructed the government’s GX Implementation Council to build new next-generation advanced reactors.

7. Mitsubishi Heavy Industries’ rosy “advanced PWR” is a farce

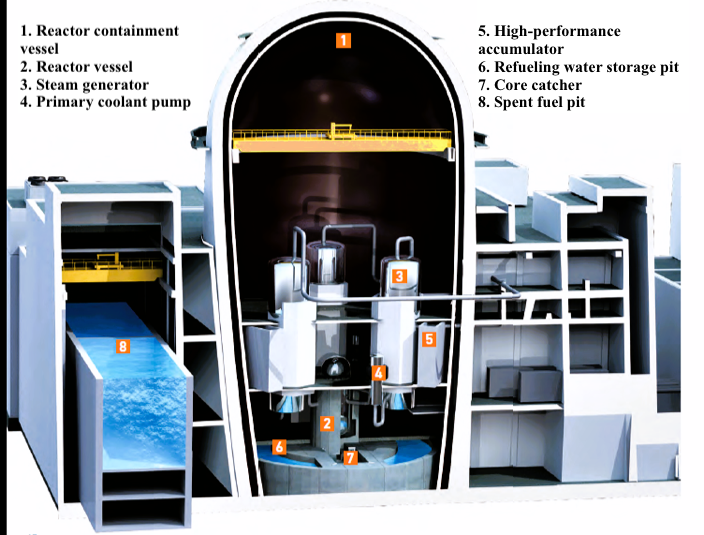

Figure 1: Diagram of the SRZ-1200, said to be under development by Mitsubishi Heavy Industries. The plant has a reinforced containment vessel and is equipped with a core catcher.

In the midst of this situation, Mitsubishi Heavy Industries made an announcement that it is working towards the development of an advanced PWR, and it looked as if the nuclear industry had suddenly come alive. However, Mitsubishi made the statement that “while there are high expectations of long-awaited new-build NPPs for a revival in the fatigued nuclear power supply chain, we sounded out the trends in each of the manufacturing companies,” but it was seen that even the fundamental countermeasures arising from lessons learnt from the Fukushima nuclear accident were concept-level measures, and it was clear that the claim of a rosy future for nuclear power was nothing more than pie in the sky.

Mitsubishi Heavy Industries said, “Our company has thus far been involved in the domestic construction and maintenance of 24 pressurized water reactors, but as we move towards the realization of a carbon neutral society, while contributing to the restart of existing plants and safe and stable operations, we are aiming for the early market entry of the SRZ-1200, the letters of the name SRZ being imbued with the following meanings: S stands for Supreme Safety and Sustainability, R stands for a Resilient light-water Reactor, and Z stands for the ultimate (Z) type of reactor that will contribute to a Zero Carbon society.” (1200 refers to an electric power output of 1200 MW.)

8. No change in either nuclear waste or the possibility of a large-scale accident

It’s as if Mitsubishi were saying that nuclear power is super-safe, more than ever before, that it is the most superior in terms of environmental problems, and that it is a sustainable technology, but it is well known for producing large amounts of radioactive substances, and while brushing aside the existence of nuclear waste that requires several tens of thousands of years to become harmless, they have the nerve to say that it is sustainable. Based on the FDNPS accident, Mitsubishi Heavy Industries group, as an PWR manufacturer, shoulder a grave responsibility for safety measures and restarts of existing NPPs. They pledged that never again would a core meltdown accident occur, but the PWRs that are currently being restarted (1) have not undergone any thoroughgoing measures against core meltdowns, such as installing a core catcher.

9. Discussion on PWR safety measures is 30 years out of date

If a core meltdown occurs in a current PWR, the thinking is that flooding the reactor with water should be abandoned and the temperature in the containment vessel should be reduced using the containment vessel spray. This means that the water sprayed into the containment vessel will accumulate right below the reactor, and molten debris will drop down into the resulting pool of water. Far from being a reactor core meltdown countermeasure, there is an extremely high risk of a steam explosion occurring. Essentially, to avoid a steam explosion, molten debris and water should not be brought into contact with one another.

(2) Sufficient countermeasures have also not been taken against hydrogen explosions. It is said that for the amount of hydrogen produced and the appearance of other flammable gases in precarious conditions, a hydrogen passive autocatalytic recombiner (PAR), whose usefulness is doubtful, would be installed. PAR’s hydrogen processing capacity is small, at 1.2kg/hour, so even if 10 devices are installed, only 12kg/hour of hydrogen would be processed. Compared with the generated amounts of hydrogen at several hundred to approximately 1,000kg, this is a minute countermeasure. Regarding hydrogen explosions, countermeasures have not been correctly taken, including for localized hydrogen flows and accumulations. In the case of PWRs, the interior of the containment vessel is not rendered inert (BRW containment vessels are filled with nitrogen to prevent hydrogen explosions), and thus the risk of a hydrogen explosion occurring is an order of magnitude higher.

(3) Ultra-strong intervening structures have been installed to protect nuclear facilities in case of aircraft impacts, but this assumes cases in which the nuclear reactor and the containment vessel have not lost their functions, and in the case of a jet fighter or large passenger aircraft colliding with a containment vessel there is nothing anyone can do. In the first place, the probability of a collision with a containment vessel in Japan is 10-7 or smaller, and so even strength assessments have not been conducted.

10. Considering Fukushima nuclear accident countermeasures once again

Since the Fukushima nuclear accident, the above (1) to (3), as well as the malfunctioning reactor water level gauge, loss of function of the release valve, isolation of the containment vessel vent line from other systems, the lack of measures for preventing malfunctions, and many other issues have consistently remained untouched. After all this, the next-generation advanced PWR SRZ-1200 (1200MW class) is said to have improved safety and reliability with “strengthened safety system facilities” and “strengthened resistance against natural disasters such as earthquakes and tsunami, as well as strengthened security against terror attacks or other contingencies.” These are said to be under development, as shown in Figure 1, based on the new regulatory standards that reflect the lessons of the FDNPS accident.

11. The fantasy that the “advanced PWR” is an ultra-safe reactor

As new safety mechanisms, a high-performance accumulator (a pressurized safety injection tank), equipment that operates automatically according to the state of the plant (passive safety equipment) and a core catcher (equipment that securely holds and cools molten debris inside the containment vessel), the world’s latest technology for molten reactor cores, are features of the plant’s design. Further, Mitsubishi Heavy Industries also says that it will be working on the design of a system that, in the unlikely event of a severe accident occurring, will reduce the amount of radioactive substances released and confine the impacts within the grounds of the NPP. They have also proclaimed that they are considering improvements in interoperability that will enable flexible responses to power fluctuations in other power supplies, such as renewable energy sources, as well as an adaptation for hydrogen production.

However, the vast majority of these are issues that have been repeatedly mentioned since the Fukushima nuclear accident. The core catcher and other features were being considered in the EU even before the Fukushima nuclear accident, and there are already plants (the EPR: European PWR, and others) that have installed them. If there is sincere reflection on the Fukushima nuclear accident, then the current PWRs, which all have safety problems, should be scrapped. At least, assuming it is possible to build a new reactor that incorporates a safe design that goes beyond the “advanced PWR,” until such an extremely safe reactor is developed, not using nuclear reactors would be the rational thing to do until such an extremely safe reactor is developed.

Masashi Goto: Born in Tokyo in 1949. Former Toshiba nuclear plant engineer. Part-time lecturer at Seisa University. Member of the Citizens’ Commission on Nuclear Energy. Member of the Contemporary Technology History Research Association. Special Member of the Special Inspection Expert Commission on the extension of the operating period of Sendai Nuclear Power Plant, Kagoshima Prefecture. Ph.D. (Engineering).

* Digital Collection of the National Diet Library, Report of the National Diet of Japan Tokyo Electric Power Company Fukushima Nuclear Power Station Accident Independent Investigation Commission (NAIIC) (In Japanese)

dl.ndl.go.jp/view/download/digidepo_3514603_po_naiic_honpen.pdf?contentNo=1&alternativeNo=

The seven recommendations can be seen on pp.22-23 of the English Executive Summary:

1 year ago

58

1 year ago

58