PITTSBURGH — Proponents of a massive Shell plastics plant in Pennsylvania promised the site would bring economic development to a long-struggling region. Those promises have failed to materialize, according to a new report.

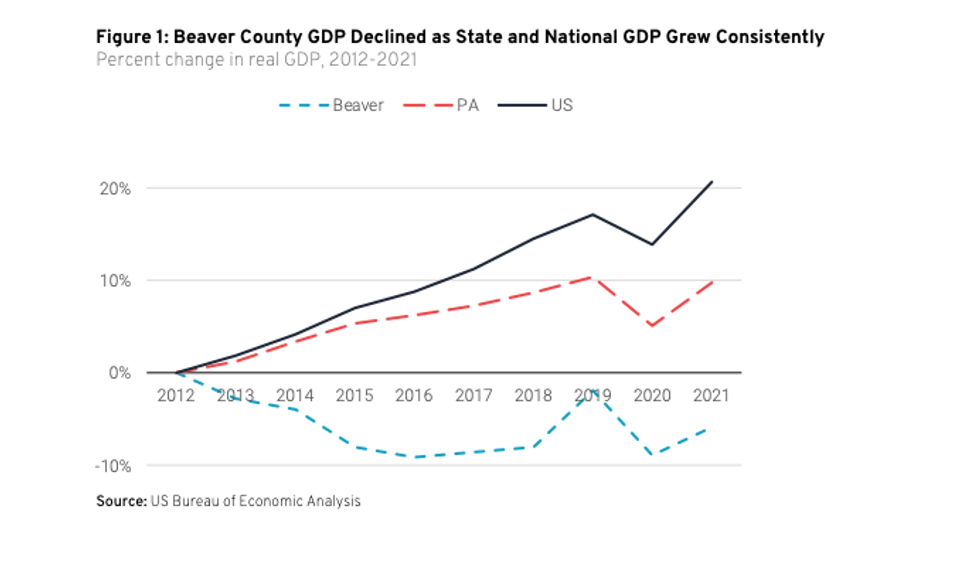

Western Pennsylvania’s Beaver County, which is home to the plant, lags behind the rest of the state and the nation in nearly every measure of economic activity, according to the report, which was authored by the Ohio River Valley Institute, a progressive, nonprofit think tank.

The report looked at the most recently available federal data from the Census Bureau, the Bureau of Labor Statistics and the Bureau of Economic Analysis, and found that since Shell’s massive petrochemical plant was proposed in 2012, Beaver County fell behind the state and the nation in job growth, even when factoring in temporary construction workers at the Shell site before it opened.

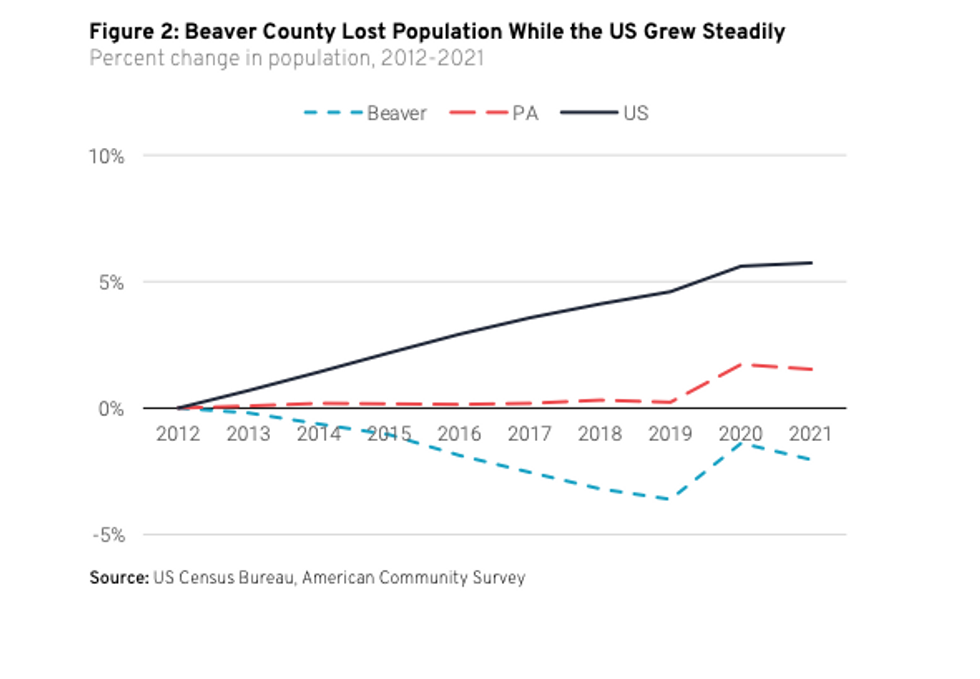

The report also found that Beaver County lost population while Pennsylvania maintained residents and the U.S. population grew. It also found the county lost businesses despite an increase in new business at the state and national levels.

“Since the announcement of the Shell petrochemical plant, Beaver County has also actually lost GDP,” Eric de Place, lead author of the report, said during a press briefing. “Not only has it fallen behind the state and the country, it has also lost ground since 2012, which is troubling.”

The report also found that since the plant was proposed in 2012, Beaver County’s poverty rate has fallen at a slower rate than average national and state poverty levels, and that the county’s child poverty rate has surpassed the state’s and the nation’s. Income levels in Beaver County rose at the same rate as in the rest of the state and the country.

Shell’s plant takes fracked ethane gas and turns it into tiny plastic pellets that are ultimately used to make plastic products like bags and packaging. Fossil fuel companies like Shell are increasingly turning toward plastics production to keep their products in demand as the transportation sector shifts toward renewables and the world decarbonizes, and many new plants like the Shell ethane cracker in Pennsylvania have been proposed throughout the U.S.

When Shell first proposed its Pennsylvania plastics plant, Pennsylvania lawmakers gave the company a $1.7 billion subsidy — the largest subsidy ever offered by the state at the time — to bring the plant to Beaver County. Many local and state politicians touted the economic benefits the plant was expected to bring to the region, while environmental and health advocates expressed concerns about the plant’s pollution and projected public health costs.

Those concerns proved valid: The plant began operations in November 2022, and by December it had already exceeded several of its yearly air pollution limits. The plant was temporarily shut down and fined $10 million dollars by the state for the violations, and several environmental advocacy groups are suing the plant for its pollution.Unmet economic projections

Many of the plant’s supporters have pointed to a study commissioned by Shell and conducted by Robert Morris University researchers in 2021, which projected that the Shell ethane cracker would bring $260 million to $846 million in annual economic activity in Beaver County alone, and an annual economic impact of approximately $3.3 billion in the surrounding 10-county region. The modeling methods used in the study were thoroughly criticized by other academics for overinflating these projections at the time.

“That Robert Morris report had tremendous flaws in terms of assumptions about economic multipliers,” Kathy Hiple, a finance professor at Bard College and former financial analyst at the Institute for Energy Economics and Financial Analysis, told Environmental Health News (EHN). Hipple conducts research for the Ohio River Valley Institute, but was not involved in the new report.

“It’s really important for people to go back now and say, let’s take stock and see if these economic benefits are coming to pass,” Hipple said. “This new study clearly shows that they aren’t.”

Brian O'Roark, the lead author of the Robert Morris study, did not respond to our request for comments on the methods used in his study and the findings in the new report.

“Do you want to move into the shadow of a petrochemical facility?”

EHN reached out to the Beaver County Chamber of Commerce and policymakers who supported the development of the Shell ethane cracker and touted the economic benefits it promised to bring to Beaver County, including Beaver County Commissioner Jack Manning and Republican state senator Elder Vogel Jr., who represents the town where the cracker plant is located. None responded to our requests for comment about the report. This story will be updated if we receive comments.

Shell spokesperson Curtis Thomas also declined to comment on the new study. After sharing the Robert Morris study and questioning the validity of the data used to conduct the new study (which are all publicly available government data), Thomas asked why Shell would be invited to comment on a study about the economic plight of Beaver County, saying the company is just there to do business. “I could tell you we certainly hope our presence here brings economic development,” he added.

DePlace noted that the Shell plant employs only a few hundred people — no more than a typical school district — and said Beaver County should serve as a cautionary tale to other economically depressed regions with dwindling populations.

“If you’re looking at moving from somewhere else, do you want to move into the shadow of a petrochemical facility, or do you want to move someplace that looks pretty similar but has great bike trails and nice restaurants?” DePlace said.

“The evidence suggests that long-term economic growth comes from making sure a community is clean and has an array of diversified local businesses, not a giant petrochemical multinational with a pollution profile that only has a few hundred workers on site.”

10 months ago

52

10 months ago

52